skurtaget pergola fabrik

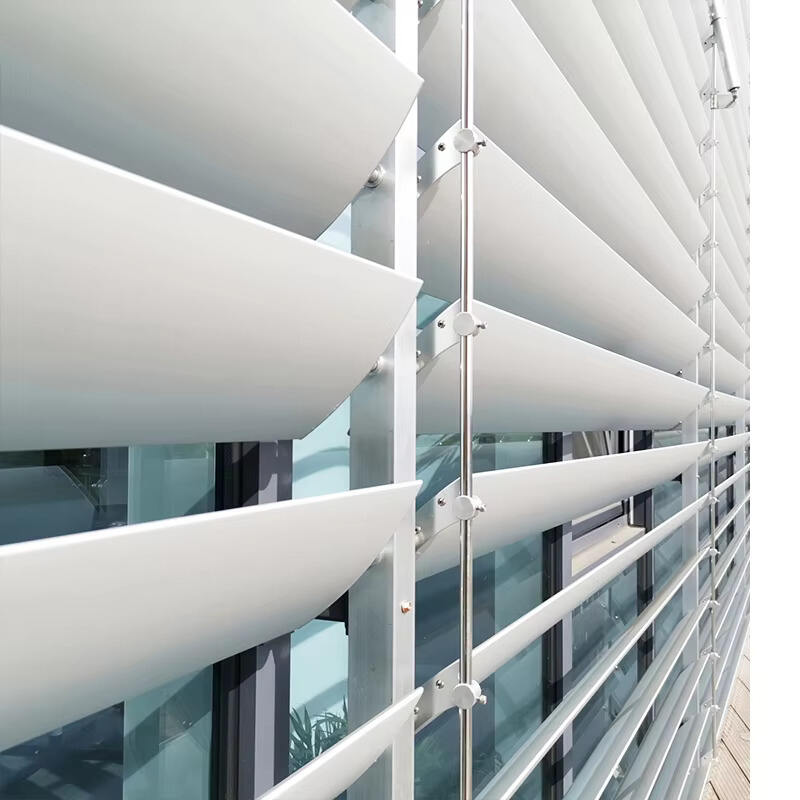

En fabrik for luvredække og pergolaer repræsenterer en moderne produktionsfacilitet, der er dedikeret til fremstilling af avancerede løsninger til udendørs liv. Denne specialiserede facilitet kombinerer præcisionsmaskinering med innovative designmuligheder for at skabe justerbare luvredæk-systemer, der transformerer udendørs områder. Fabrikken anvender avanceret automations teknologi og computerstyrede produktionsprocesser for at sikre konstant kvalitet i alle producerede komponenter. Facilitetens produktionslinje omfatter forskellige faser, fra råmaterialebehandling til endelig samling, med strenge kvalitetskontrolforanstaltninger, der er implementeret i hvert trin. Avancerede aluminiumsprofiludtrækningsudstyr gør det muligt at fremstille holdbare og vejrresistente luvreblade, mens sofistikerede pulverlakeringssystemer sikrer en overlegen finishkvalitet og levetid. Fabrikkens tekniske kapacitet strækker sig også til tilpassede løsninger, hvilket gør det muligt at producere pergolaer i forskellige størrelser og konfigurationer for at opfylde de specifikke krav fra kunderne. Desuden har faciliteten moderne testfaciliteter til at verificere produkternes holdbarhed, vejrmodstandsevne og mekaniske pålidelighed. Med integrerede forsknings- og udviklingsafdelinger arbejder fabrikken løbende på at forbedre designelementer og inkorporere nye teknologier for at forbedre produktets ydelse og brugeroplevelsen.