custom blinds factory

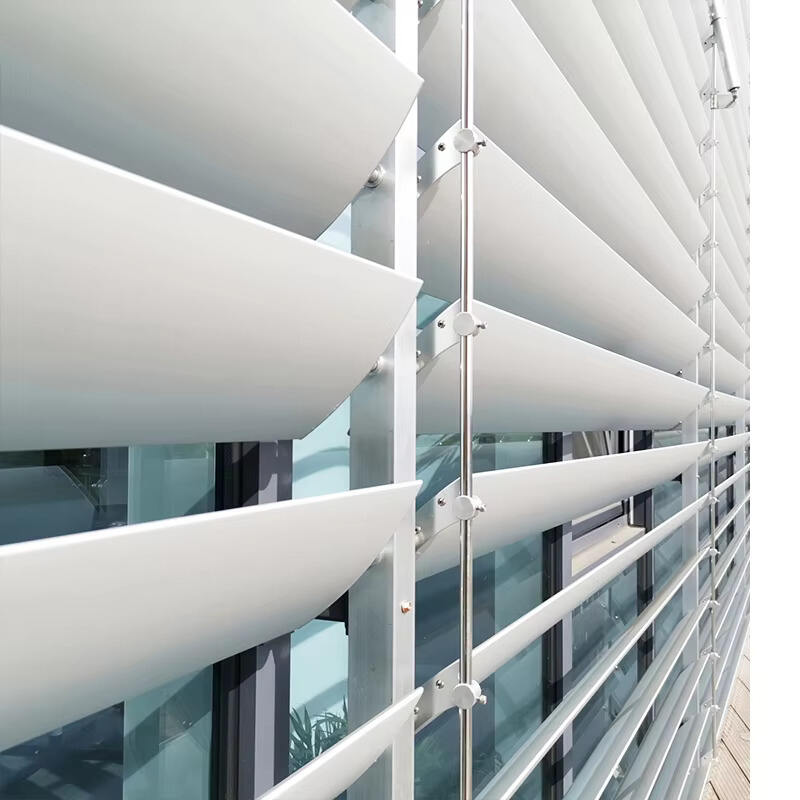

A custom blinds factory represents a state-of-the-art manufacturing facility dedicated to producing tailored window treatments that perfectly match customers' specifications. These advanced facilities combine modern automation with skilled craftsmanship to create precision-engineered window blinds that meet diverse aesthetic and functional requirements. The factory utilizes cutting-edge machinery for precise cutting, assembly, and quality control, ensuring each blind meets exact measurements and specifications. Advanced computer-aided design (CAD) systems enable accurate pattern creation and material optimization, while automated cutting tables ensure precise dimensions for every component. The facility houses specialized areas for different manufacturing processes, including material preparation, cutting, assembly, and finishing. Quality control stations equipped with modern testing equipment verify durability, light filtration, and operational smoothness. The factory maintains a comprehensive inventory of materials, including aluminum, wood, fabric, and synthetic materials, allowing for quick production turnaround. Environmental control systems maintain optimal temperature and humidity levels for material stability during manufacturing. The facility also features a dedicated research and development department that continuously works on innovating new designs and improving existing products to meet evolving market demands.